| Sign In | Join Free | My wpc-board.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My wpc-board.com |

|

Brand Name : JIA SHAN

Model Number : DIN, ASEM, ISO

Certification : ISO

Place of Origin : China

MOQ : 100

Price : USD0.2/pcs-USD1/pcs

Payment Terms : T/T, Western Union

Supply Ability : Batch order abailable

Delivery Time : 1-5 weekds

Usage : Fastening

Size : Various sizes available

Style : steel hex head with washer nut

Head Style : Hexagon head

Strength : High

Finish : Polished/Zinc/ Anodizing

Manufacturer : JIA SHAN Hardward Company

Length : As customisation

Package : Small Packing+Carton Packing+Pallet

Standard : DIN

Package Quantity : 100 pieces

Shape : Bolt

Measurement System : INCH, Metric

Port : Shenzhen

Quality : Inspection before shipment

Color : As customisation

Material : Carbon Steel

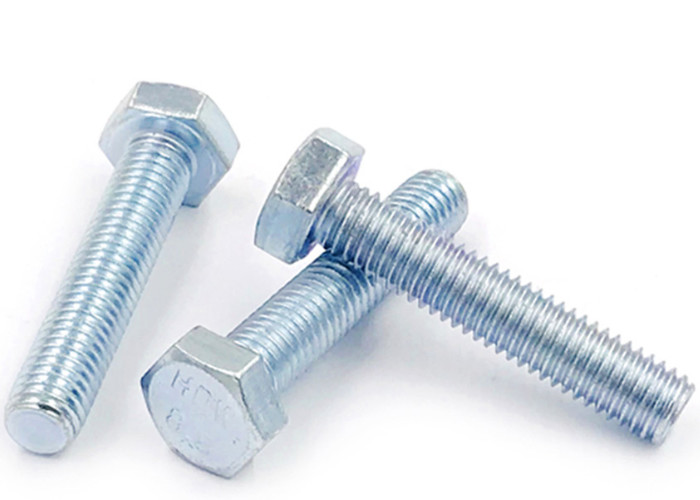

Hexagon Bolt M8 9/16 Inch Grade 4.8 Galvanized Corrosion-Resistant Industrial Applications

Product Description:

This hexagon bolt is crafted from SS304 stainless steel, which offers superior resistance to corrosion, rust, and oxidation. SS304 is highly durable in both fresh and saltwater environments, making it an excellent choice for applications in harsh industrial settings or outdoor installations. The bolt features an M8 size with a 9/16-inch thread, offering a secure fit and reliable fastening in various mechanical assemblies. Graded at 4.8, it provides sufficient strength for general industrial use, such as in equipment, machinery, and piping systems. Additionally, the galvanized finish adds another layer of corrosion protection, particularly useful in coastal or humid environments where exposure to water and chemicals is frequent. The bolt is suitable for industries such as manufacturing, construction, and automotive, where long-lasting, rust-resistant performance is crucial.

Applications

Galvanising is a surface treatment technique whereby a layer of zinc is deposited on the surface of a metal, alloy or other material to provide aesthetic appeal and to prevent rusting.The main method used is hot-dip galvanising.

Zinc is soluble in acids and alkalis, so it is called an amphoteric metal.Zinc hardly changes in dry air.In humid air, a dense film of alkaline zinc carbonate is formed on the surface of zinc.In containing sulfur dioxide, hydrogen sulfide and marine atmosphere, zinc corrosion resistance is poor, especially in the high temperature and high humidity containing organic acid atmosphere, zinc coating is very easy to be corroded.The standard electrode potential of zinc is -0.76V, for the steel substrate, zinc coating belongs to the anodic coating, it is mainly used to prevent the corrosion of steel, its protective properties of the advantages and disadvantages of the thickness of the coating is very big.Zinc coating can significantly improve its protective and decorative properties after passivation treat

There are two types of galvanising solutions: cyanide plating solutions and cyanide-free plating solutions.Cyanide plating solution is divided into microcyanide, low cyanide, medium cyanide, and high cyanide categories.Cyanide-free plating solutions include alkaline zincate plating solution, ammonium salt plating solution, sulphate plating solution and ammonia-free chloride plating solution.Cyanide zinc plating solution has good even plating ability, and the plating layer obtained is smooth and detailed, which has been used for a long time in the production.However, due to cyanide toxicity, serious environmental pollution, in recent years has tended to use low-cyanide, micro-cyanide, cyanide-free zinc plating solution.

| No. | C% | Cr% | Ni % | Mo % |

| 304 | 0.07 | 17.5-19.5 | 8.0-10.5 | / |

| 316 | 0.08 | 16.0-18.0 | 10.0-14.0 | 2.00-3.00 |

| 301 | 0.15 | 16.0-18.1 | 6-8 | / |

| 310 | 0.08 | 24-26 | 19-22 | / |

About Us

Package

|

|

Hexagon Bolt M8 9/16 Inch Grade 4.8 Galvanized Corrosion-Resistant Industrial Applications Images |